Please Choose Your Language

NEK-CBXAN M30*3.5 (M30x3.5xYH5x135L)

NEK

NEK-CBXAN M30*3.5 (M30x3.5xYH5x135L)

1pcs

| Availability: | |

|---|---|

| Quantity: | |

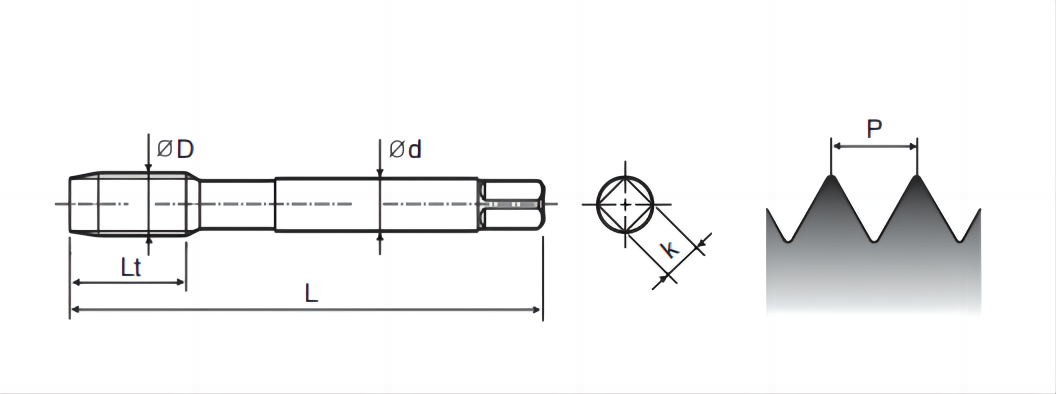

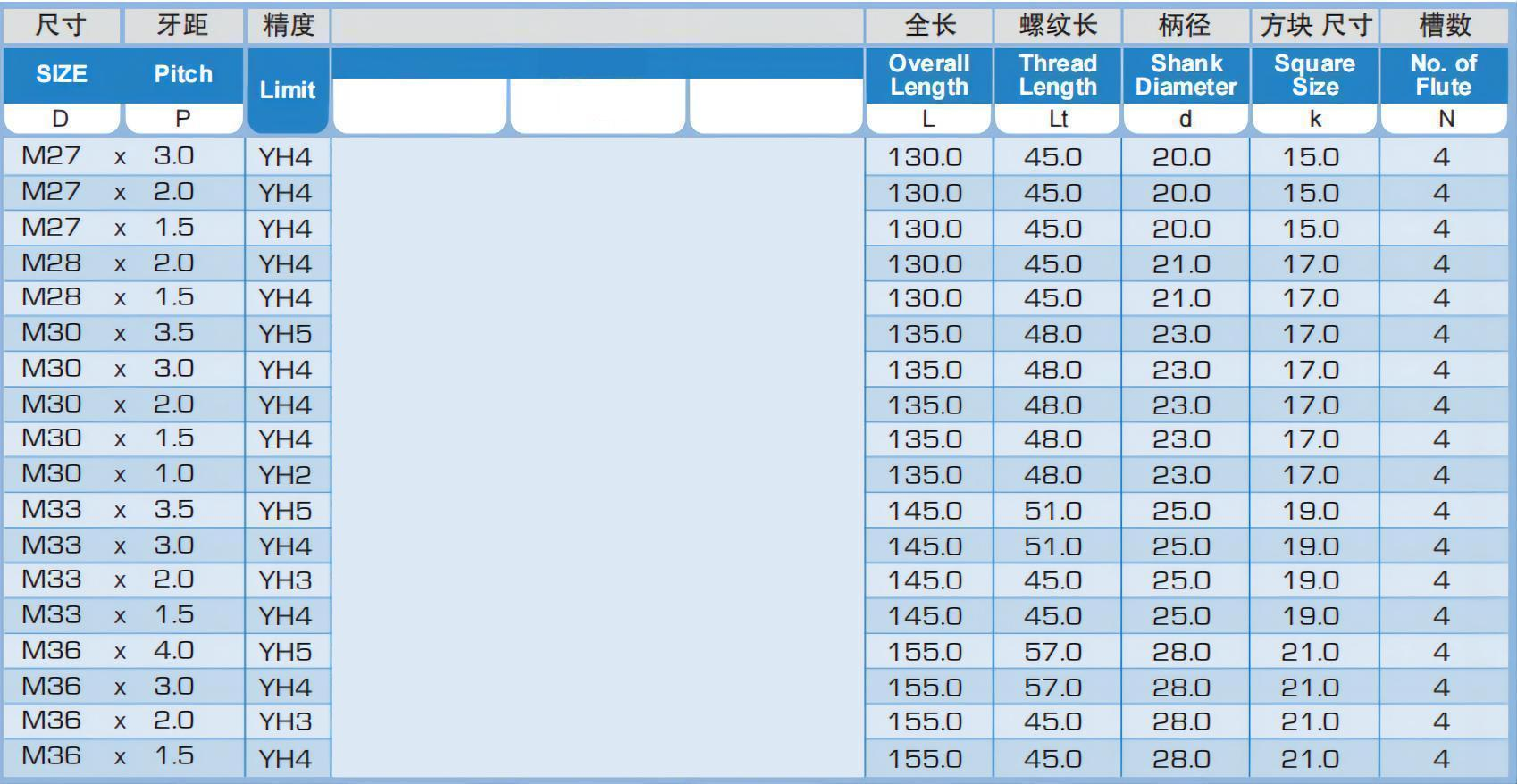

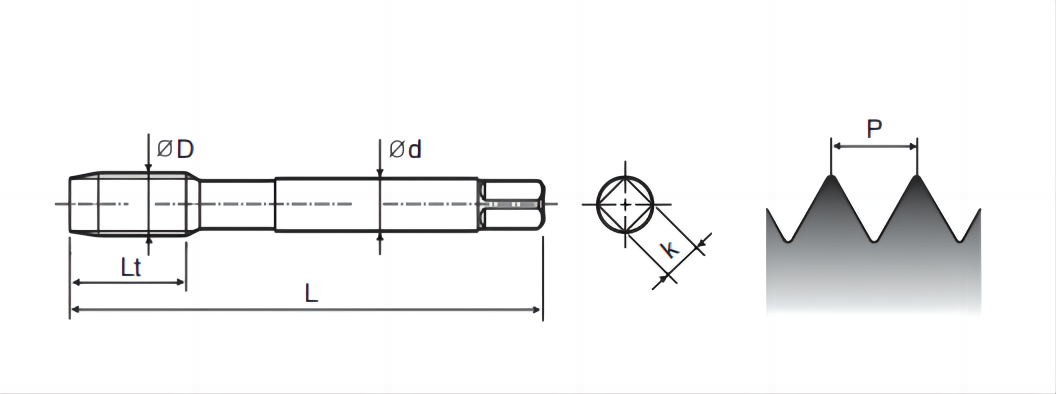

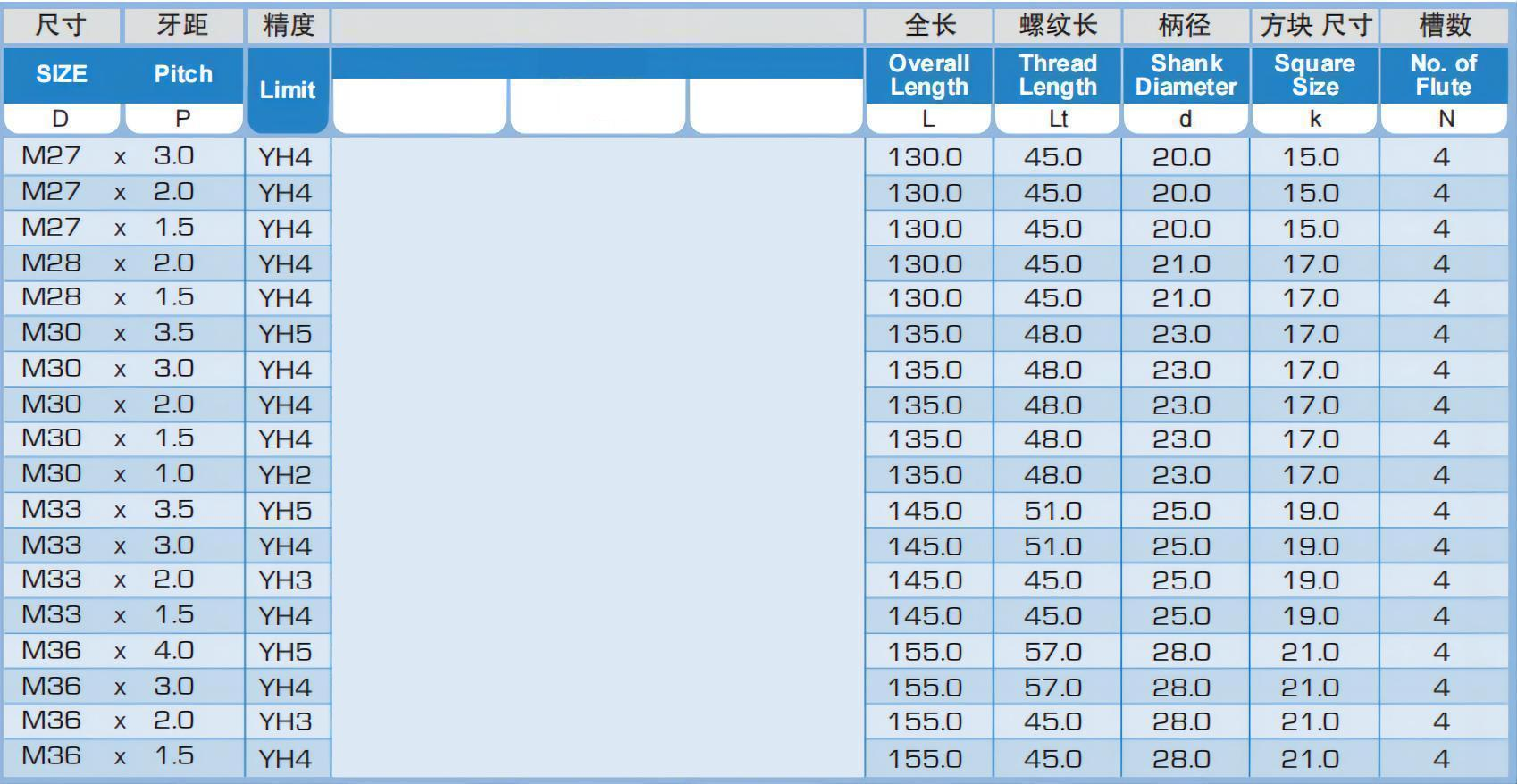

The NEK-CBXAN M30X3.5 Multipurpose Tip Tap is a heavy-duty threading solution engineered for versatility across carbon steel (A36, 1045), alloy steel (4130), and austenitic stainless steel (304, 316). Its dual-angle tip design (15° lead-in + 30° clearance) is precision-ground using a 5-axis CNC grinder, enabling seamless transitions between through-hole (unlimited depth) and blind-hole (up to 5× diameter) operations. The M30X3.5 thread specification (pitch 3.5mm) is optimized for ISO metric coarse threads in structural steel applications, with a thread form accuracy of ≤0.02mm per 25mm length.

Multipurpose Tip Design: Incorporates a variable helix flute (25°–35°) with a parabolic cross-section for improved chip evacuation in both ferrous and non-ferrous materials. The polished flute surface (Ra 0.8μm) undergoes a diamond-like carbon (DLC) treatment to reduce chip adhesion by 40%.

M30X3.5 Thread Size: Manufactured to DIN 352 standards with a thread runout of ≤0.05mm, ensuring compatibility with M30 bolts in construction-grade assemblies (tensile class 8.8 and above).

Durable Carbide-Tipped Construction: Tungsten carbide tip (WC-Co, 90% WC) with a cobalt binder content of 10% is brazed to a high-speed steel (HSS-E) shank using silver-copper alloy (melting point 780°C). This combination provides wear resistance in HRC 30–40 steel and impact resistance for intermittent cutting in structural applications.

Widely utilized in structural steel fabrication (bridge girders with yield strength ≥345 MPa, building frameworks), oil & gas pipeline construction (API 5L X65/X70 flange connections), and mining equipment manufacturing (axle housings for 50-ton+ haul trucks). It is certified for use in ASME B1.13M metric thread applications and meets ISO 9001:2015 quality management system requirements for critical structural joints.

Q: What spindle speed is recommended for carbon steel?

A: 8–12 m/min for 1045 steel (HB 180–220); reduce by 20% for stainless steel (304) to minimize work-hardening and 15% for alloy steel (4130) to manage heat buildup.

Q: Can it be reconditioned after wear?

A: Yes, the carbide tip can be re-ground up to 3 times using diamond grinding wheels (120–180 grit) before dimensional limits (thread depth reduction ≥0.15mm) are exceeded.

Q: Is it suitable for vertical and horizontal machining?

A: Yes, with coolant pressure ≥5 bar in horizontal applications to prevent chip. For vertical upward machining, use air blast auxiliary chip removal to avoid chip recutting.

The NEK-CBXAN M30X3.5 Multipurpose Tip Tap is a heavy-duty threading solution engineered for versatility across carbon steel (A36, 1045), alloy steel (4130), and austenitic stainless steel (304, 316). Its dual-angle tip design (15° lead-in + 30° clearance) is precision-ground using a 5-axis CNC grinder, enabling seamless transitions between through-hole (unlimited depth) and blind-hole (up to 5× diameter) operations. The M30X3.5 thread specification (pitch 3.5mm) is optimized for ISO metric coarse threads in structural steel applications, with a thread form accuracy of ≤0.02mm per 25mm length.

Multipurpose Tip Design: Incorporates a variable helix flute (25°–35°) with a parabolic cross-section for improved chip evacuation in both ferrous and non-ferrous materials. The polished flute surface (Ra 0.8μm) undergoes a diamond-like carbon (DLC) treatment to reduce chip adhesion by 40%.

M30X3.5 Thread Size: Manufactured to DIN 352 standards with a thread runout of ≤0.05mm, ensuring compatibility with M30 bolts in construction-grade assemblies (tensile class 8.8 and above).

Durable Carbide-Tipped Construction: Tungsten carbide tip (WC-Co, 90% WC) with a cobalt binder content of 10% is brazed to a high-speed steel (HSS-E) shank using silver-copper alloy (melting point 780°C). This combination provides wear resistance in HRC 30–40 steel and impact resistance for intermittent cutting in structural applications.

Widely utilized in structural steel fabrication (bridge girders with yield strength ≥345 MPa, building frameworks), oil & gas pipeline construction (API 5L X65/X70 flange connections), and mining equipment manufacturing (axle housings for 50-ton+ haul trucks). It is certified for use in ASME B1.13M metric thread applications and meets ISO 9001:2015 quality management system requirements for critical structural joints.

Q: What spindle speed is recommended for carbon steel?

A: 8–12 m/min for 1045 steel (HB 180–220); reduce by 20% for stainless steel (304) to minimize work-hardening and 15% for alloy steel (4130) to manage heat buildup.

Q: Can it be reconditioned after wear?

A: Yes, the carbide tip can be re-ground up to 3 times using diamond grinding wheels (120–180 grit) before dimensional limits (thread depth reduction ≥0.15mm) are exceeded.

Q: Is it suitable for vertical and horizontal machining?

A: Yes, with coolant pressure ≥5 bar in horizontal applications to prevent chip. For vertical upward machining, use air blast auxiliary chip removal to avoid chip recutting.

Phone: +86-18868651999

Email: eden0906@nekkk.com

Add: ROOM 1-2, 17TH FLOOR, 9TH BUILDING, NO.35, XINGHAI ROAD(NORTH), GAOXIN DISTRICT, NINGBO CITY, ZHEJIANG PROVINCE, CHINA