Please Choose Your Language

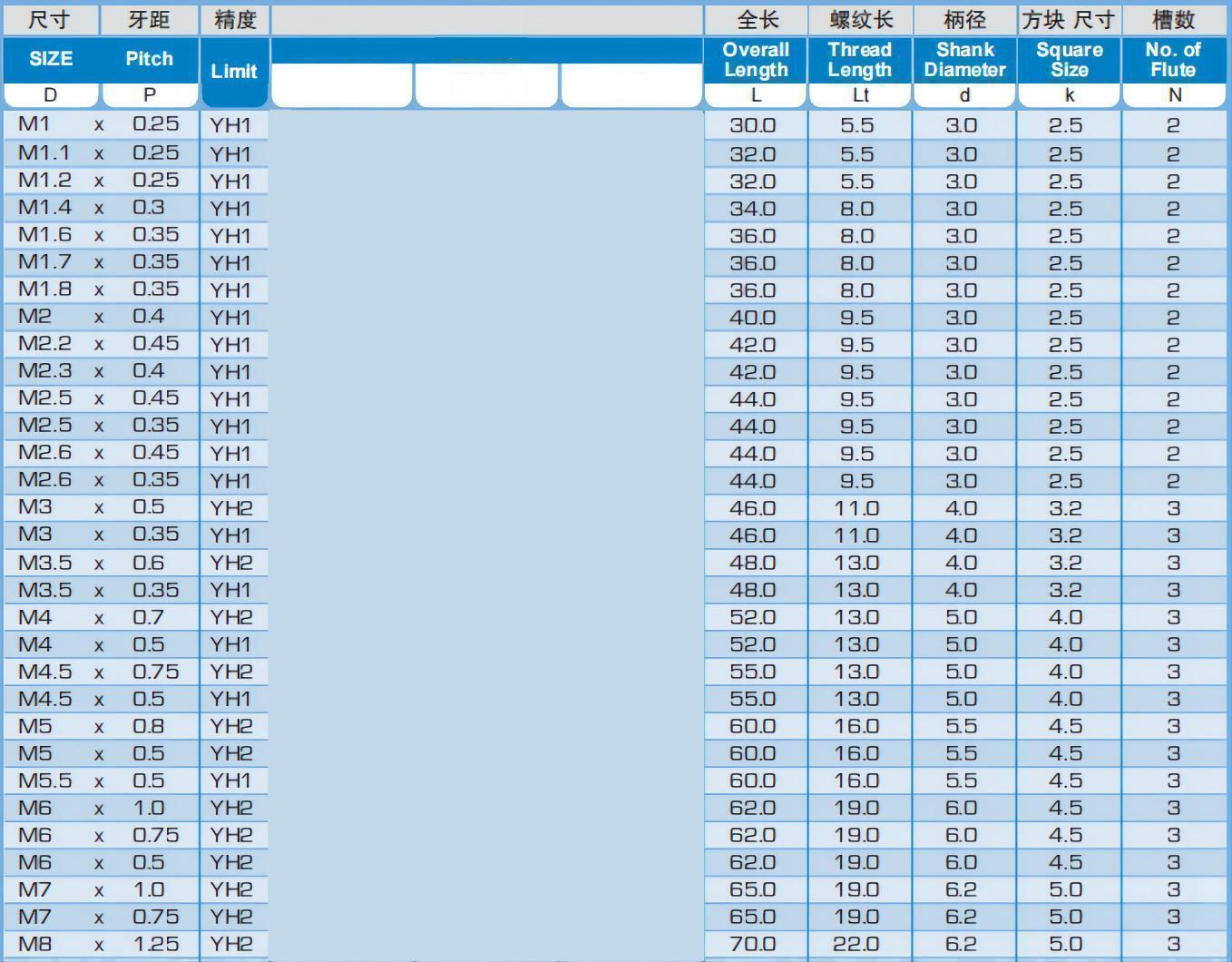

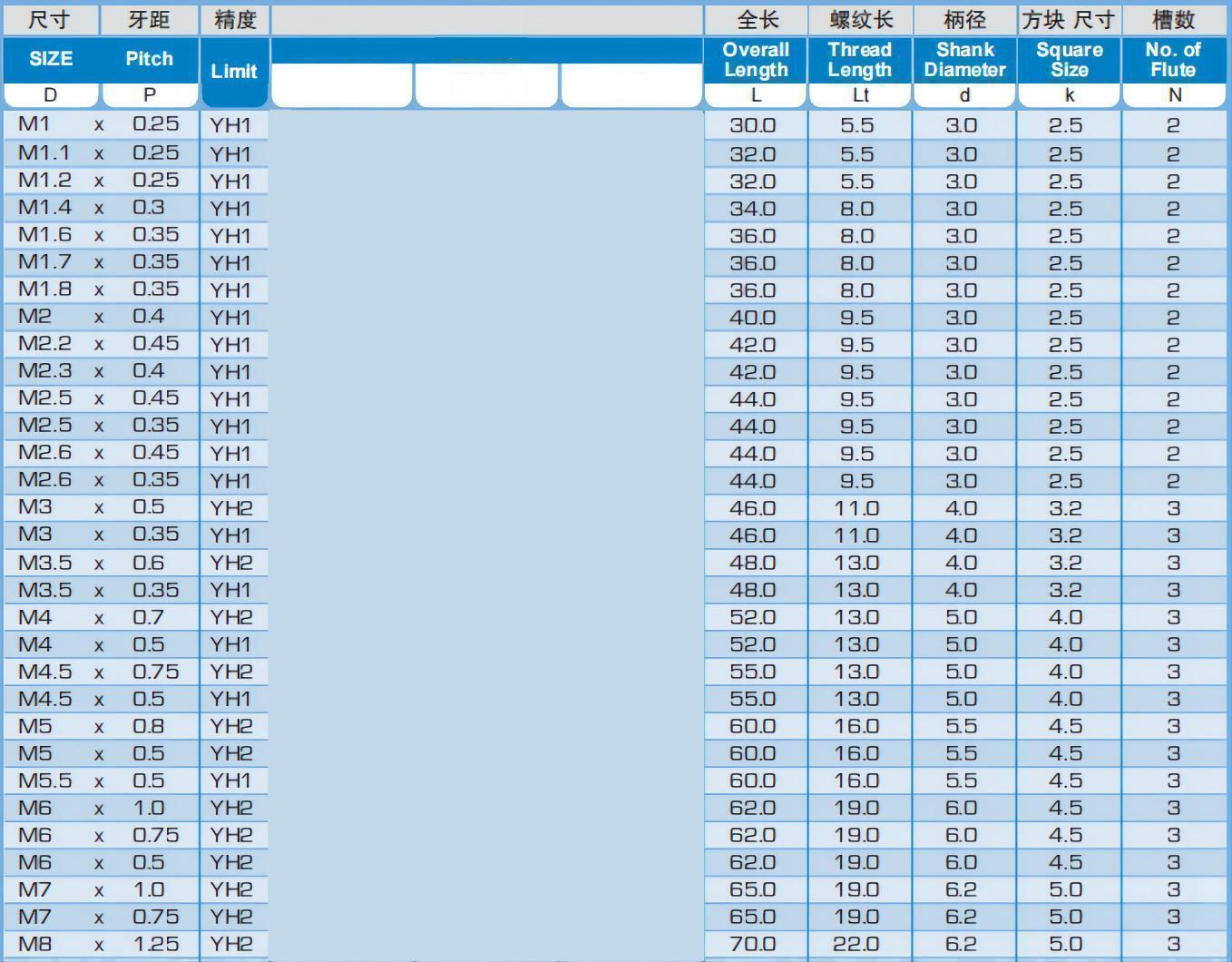

NEK-CBLUO M8*1.25 (M8x1.25xYH2x70L)

NEK

NEK-T2809-0022

screw tap

Automobile, machine tool, aviation, mould

10PCS

| Availability: | |

|---|---|

| Quantity: | |

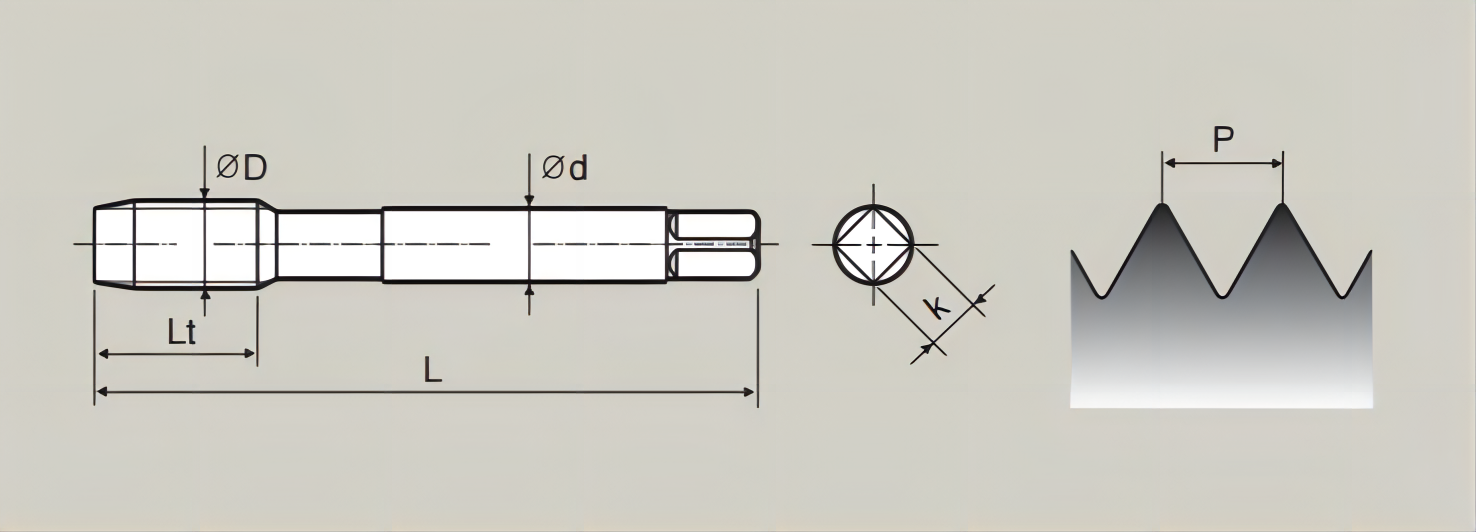

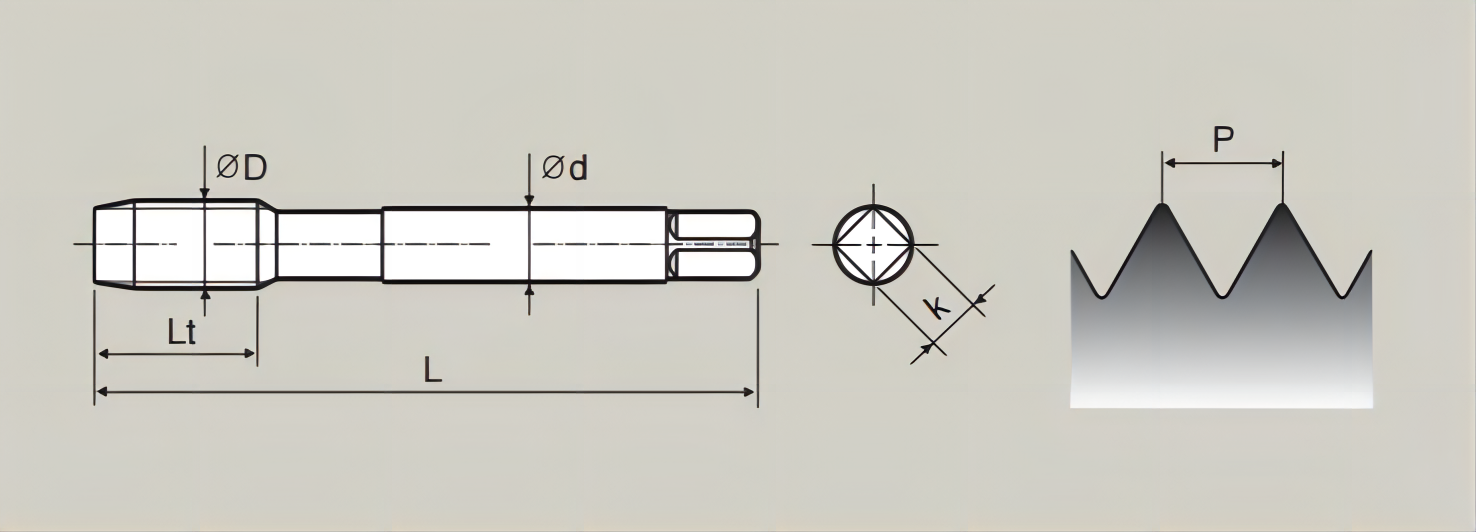

The YH2-Coated M8x1.25 Screw Tap is a precision-engineered threading tool developed specifically for high-performance operations on alloy steel. Its core design integrates advanced material science with industrial machining requirements: the YH2 coating, a nanocomposite surface treatment composed of titanium aluminum nitride (TiAlN) derivatives, forms a protective layer with a thickness of 3–5μm. This coating undergoes a 3-stage deposition process (ion cleaning, base layer formation, topcoat curing) to ensure uniform adhesion. Combined with a precision-ground thread profile of M8x1.25 (pitch 1.25mm), the tool maintains consistent thread geometry across 40–50 consecutive holes in alloy steel before requiring maintenance, outperforming uncoated taps by 30% in batch production scenarios.

YH2 Coating: Delivers a hardness rating of 3200–3500 HV, reducing friction coefficient by 30% compared to uncoated taps. This minimizes heat generation during high-speed machining (12–18 m/min) on alloy steel, with a maximum operating temperature of 450°C.

Precision Dimensions (M8x1.25): Tolerance controlled within ISO 286-2 h6 standards, ensuring thread fit with Class 6g fasteners. The lead-in chamfer (3–5 threads) features a polished transition radius (0.2mm) to facilitate easy alignment in both blind and through holes.

High-Strength Core Material: Constructed from tungsten-molybdenum alloy steel (W6Mo5Cr4V2) vacuum quenching, providing tensile strength of 1800–2000 MPa. This material composition ensures sustained performance in 4140/4340 steel applications, even under cyclic loading.

Primary applications include threading alloy steel transmission gears (automotive powertrains, where torque resistance up to 350 N·m is required), hydraulic cylinder rods (industrial machinery with operating pressures of 20–30 MPa), and aircraft structural brackets (meeting ASTM A434 standards). It is particularly effective in batch production environments where consistent thread quality (Class 4H5H) is critical for assembly line efficiency, reducing rework rates by approximately 15% compared to standard taps.

Q: What is the maximum hole depth it can handle?

A: Suitable for blind holes up to 3× diameter (24mm) with proper chip evacuation. For deeper holes, consider using a spiral-flute variant to enhance chip removal.

Q: Does it require special toolholder?

A: Compatible with standard ER collet holders (ER20 and above); rigid toolholders with coolant-through capability are recommended for high-torque applications exceeding 120 N·m.

Q: What is the expected tool life?

A: Average lifespan of 800–1200 holes in 4140 steel under optimal cooling conditions (coolant flow rate ≥5 L/min). Tool life decreases by 20–25% in 4340 steel due to higher material hardness.

The YH2-Coated M8x1.25 Screw Tap is a precision-engineered threading tool developed specifically for high-performance operations on alloy steel. Its core design integrates advanced material science with industrial machining requirements: the YH2 coating, a nanocomposite surface treatment composed of titanium aluminum nitride (TiAlN) derivatives, forms a protective layer with a thickness of 3–5μm. This coating undergoes a 3-stage deposition process (ion cleaning, base layer formation, topcoat curing) to ensure uniform adhesion. Combined with a precision-ground thread profile of M8x1.25 (pitch 1.25mm), the tool maintains consistent thread geometry across 40–50 consecutive holes in alloy steel before requiring maintenance, outperforming uncoated taps by 30% in batch production scenarios.

YH2 Coating: Delivers a hardness rating of 3200–3500 HV, reducing friction coefficient by 30% compared to uncoated taps. This minimizes heat generation during high-speed machining (12–18 m/min) on alloy steel, with a maximum operating temperature of 450°C.

Precision Dimensions (M8x1.25): Tolerance controlled within ISO 286-2 h6 standards, ensuring thread fit with Class 6g fasteners. The lead-in chamfer (3–5 threads) features a polished transition radius (0.2mm) to facilitate easy alignment in both blind and through holes.

High-Strength Core Material: Constructed from tungsten-molybdenum alloy steel (W6Mo5Cr4V2) vacuum quenching, providing tensile strength of 1800–2000 MPa. This material composition ensures sustained performance in 4140/4340 steel applications, even under cyclic loading.

Primary applications include threading alloy steel transmission gears (automotive powertrains, where torque resistance up to 350 N·m is required), hydraulic cylinder rods (industrial machinery with operating pressures of 20–30 MPa), and aircraft structural brackets (meeting ASTM A434 standards). It is particularly effective in batch production environments where consistent thread quality (Class 4H5H) is critical for assembly line efficiency, reducing rework rates by approximately 15% compared to standard taps.

Q: What is the maximum hole depth it can handle?

A: Suitable for blind holes up to 3× diameter (24mm) with proper chip evacuation. For deeper holes, consider using a spiral-flute variant to enhance chip removal.

Q: Does it require special toolholder?

A: Compatible with standard ER collet holders (ER20 and above); rigid toolholders with coolant-through capability are recommended for high-torque applications exceeding 120 N·m.

Q: What is the expected tool life?

A: Average lifespan of 800–1200 holes in 4140 steel under optimal cooling conditions (coolant flow rate ≥5 L/min). Tool life decreases by 20–25% in 4340 steel due to higher material hardness.

Phone: +86-18868651999

Email: eden0906@nekkk.com

Add: ROOM 1-2, 17TH FLOOR, 9TH BUILDING, NO.35, XINGHAI ROAD(NORTH), GAOXIN DISTRICT, NINGBO CITY, ZHEJIANG PROVINCE, CHINA