Please Choose Your Language

DNMG15

NEK

1

1

Cubic Boron Nitride

Car

1 Box- 10 PCS

Carton

| Availability: | |

|---|---|

| Quantity: | |

Product Overview

Product OverviewThe DNMG15 is a versatile turning insert meticulously engineered for stainless steel machining, encompassing austenitic (e.g., SUS304, SUS316) and martensitic grades. Stainless steel presents unique challenges such as work-hardening and excessive heat generation during machining, and this insert's advanced coating and specialized geometry are specifically designed to address these issues. It offers reliable performance across a range of stainless steel machining applications, making it a valuable tool in various manufacturing settings.

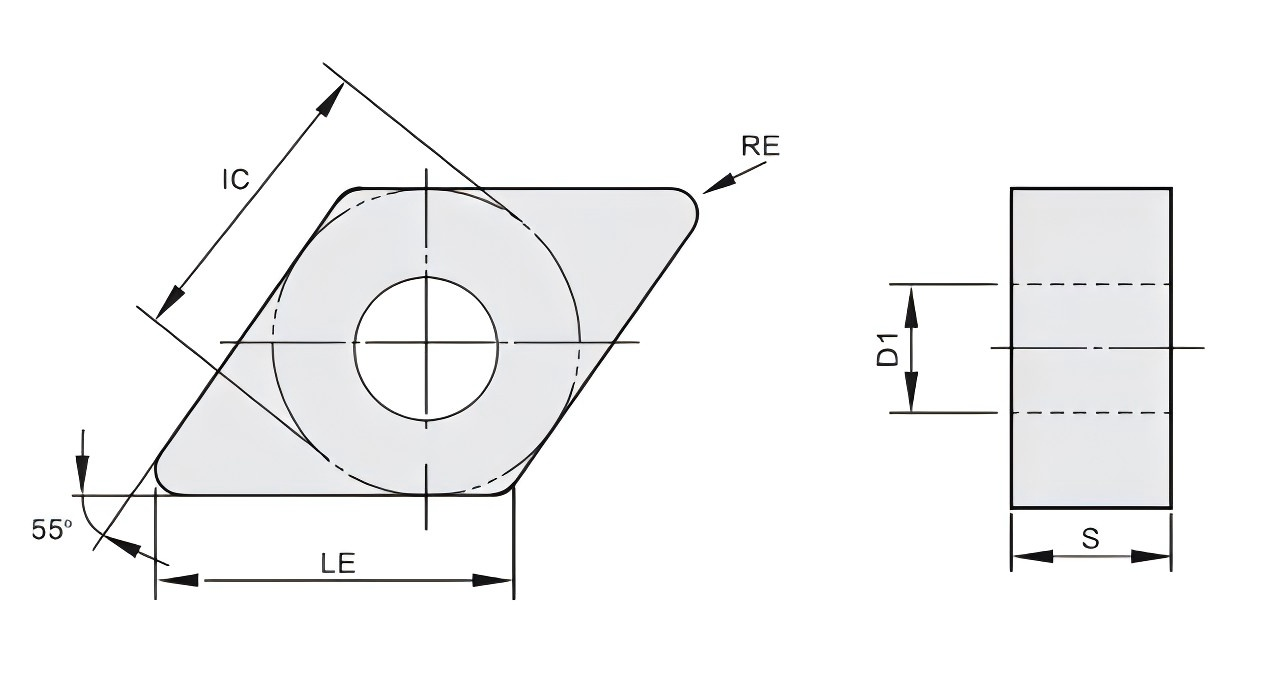

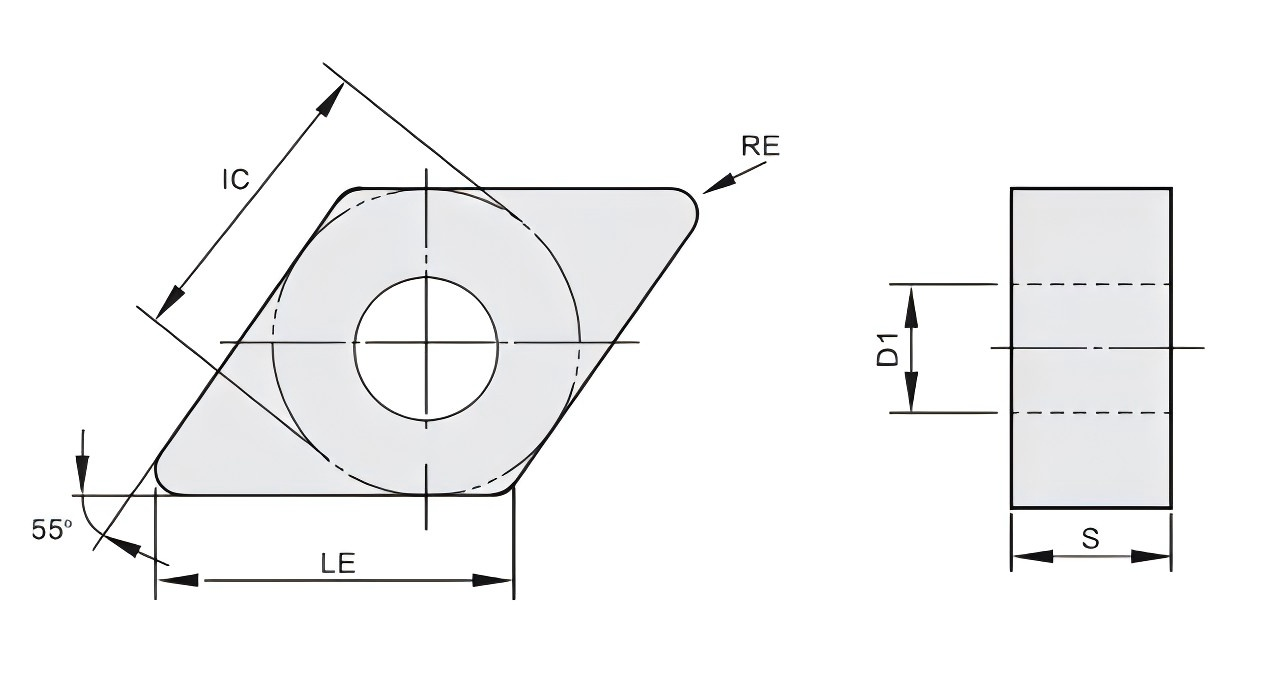

DNMG15 Geometry: The 55° diamond shape, with a 0.4–1.2 mm corner radius, is carefully designed to balance cutting force and edge strength. This balance is crucial when machining stainless steel, as it helps prevent tool failure and ensures consistent cutting performance.

CA4505 Coating: Featuring a CVD Al₂O₃ coating, the insert provides superior heat resistance, which is essential for withstanding the high temperatures generated during stainless steel machining. Additionally, it offers excellent anti-welding properties, reducing built-up edge (BUE) formation. BUE can negatively impact surface finish and tool life, so this feature is highly beneficial .

Substrate Design: The insert utilizes a gradient-structured carbide substrate that combines high hardness with fracture toughness. This unique substrate design ensures durability in long-term machining operations, even when faced with the abrasive nature of stainless steel.

Cutting Speed: 60–105 m/min for austenitic stainless steel and 50–80 m/min for martensitic grades, reflecting the different machining characteristics of these materials.

Feed Rate: 0.11–0.42 mm/rev, allowing for precise control over material removal.

Depth of Cut: 0.5–3.0 mm, suitable for various machining depths in stainless steel components.

Industry: Commonly used in chemical processing, food equipment, and medical device manufacturing industries. These sectors require high-quality machining of stainless steel due to its corrosion resistance properties.

Operations: Specialized in turning of stainless steel pipes, valves, and fittings, where corrosion resistance and surface integrity are critical factors. The insert's performance ensures that these components meet the strict standards of their respective industries.

Machining Scenarios: Suitable for both wet and dry machining environments. When using coolant, reduced pressure is recommended to avoid thermal shock, which can damage the insert and affect machining results.

Q: How does the DNMG15 prevent BUE in austenitic stainless steel?

A: The smooth CA4505 coating minimizes material adhesion to the insert's surface. Simultaneously, the sharp edge geometry promotes clean chip separation, reducing the likelihood of BUE formation, which is a common issue in austenitic stainless steel machining .

Q: Can it be used for other materials?

A: Yes, beyond stainless steel, it also performs well in heat-resistant alloys (e.g., Inconel) and cast iron. However, it is important to adjust the machining parameters accordingly to optimize performance for these alternative materials.

Product Overview

Product OverviewThe DNMG15 is a versatile turning insert meticulously engineered for stainless steel machining, encompassing austenitic (e.g., SUS304, SUS316) and martensitic grades. Stainless steel presents unique challenges such as work-hardening and excessive heat generation during machining, and this insert's advanced coating and specialized geometry are specifically designed to address these issues. It offers reliable performance across a range of stainless steel machining applications, making it a valuable tool in various manufacturing settings.

DNMG15 Geometry: The 55° diamond shape, with a 0.4–1.2 mm corner radius, is carefully designed to balance cutting force and edge strength. This balance is crucial when machining stainless steel, as it helps prevent tool failure and ensures consistent cutting performance.

CA4505 Coating: Featuring a CVD Al₂O₃ coating, the insert provides superior heat resistance, which is essential for withstanding the high temperatures generated during stainless steel machining. Additionally, it offers excellent anti-welding properties, reducing built-up edge (BUE) formation. BUE can negatively impact surface finish and tool life, so this feature is highly beneficial .

Substrate Design: The insert utilizes a gradient-structured carbide substrate that combines high hardness with fracture toughness. This unique substrate design ensures durability in long-term machining operations, even when faced with the abrasive nature of stainless steel.

Cutting Speed: 60–105 m/min for austenitic stainless steel and 50–80 m/min for martensitic grades, reflecting the different machining characteristics of these materials.

Feed Rate: 0.11–0.42 mm/rev, allowing for precise control over material removal.

Depth of Cut: 0.5–3.0 mm, suitable for various machining depths in stainless steel components.

Industry: Commonly used in chemical processing, food equipment, and medical device manufacturing industries. These sectors require high-quality machining of stainless steel due to its corrosion resistance properties.

Operations: Specialized in turning of stainless steel pipes, valves, and fittings, where corrosion resistance and surface integrity are critical factors. The insert's performance ensures that these components meet the strict standards of their respective industries.

Machining Scenarios: Suitable for both wet and dry machining environments. When using coolant, reduced pressure is recommended to avoid thermal shock, which can damage the insert and affect machining results.

Q: How does the DNMG15 prevent BUE in austenitic stainless steel?

A: The smooth CA4505 coating minimizes material adhesion to the insert's surface. Simultaneously, the sharp edge geometry promotes clean chip separation, reducing the likelihood of BUE formation, which is a common issue in austenitic stainless steel machining .

Q: Can it be used for other materials?

A: Yes, beyond stainless steel, it also performs well in heat-resistant alloys (e.g., Inconel) and cast iron. However, it is important to adjust the machining parameters accordingly to optimize performance for these alternative materials.

Phone: +86-18868651999

Email: eden0906@nekkk.com

Add: ROOM 1-2, 17TH FLOOR, 9TH BUILDING, NO.35, XINGHAI ROAD(NORTH), GAOXIN DISTRICT, NINGBO CITY, ZHEJIANG PROVINCE, CHINA