Please Choose Your Language

WNMG080408-DF PC8315T

SHITAEGER

NEK-WNMG81

Turning Insert

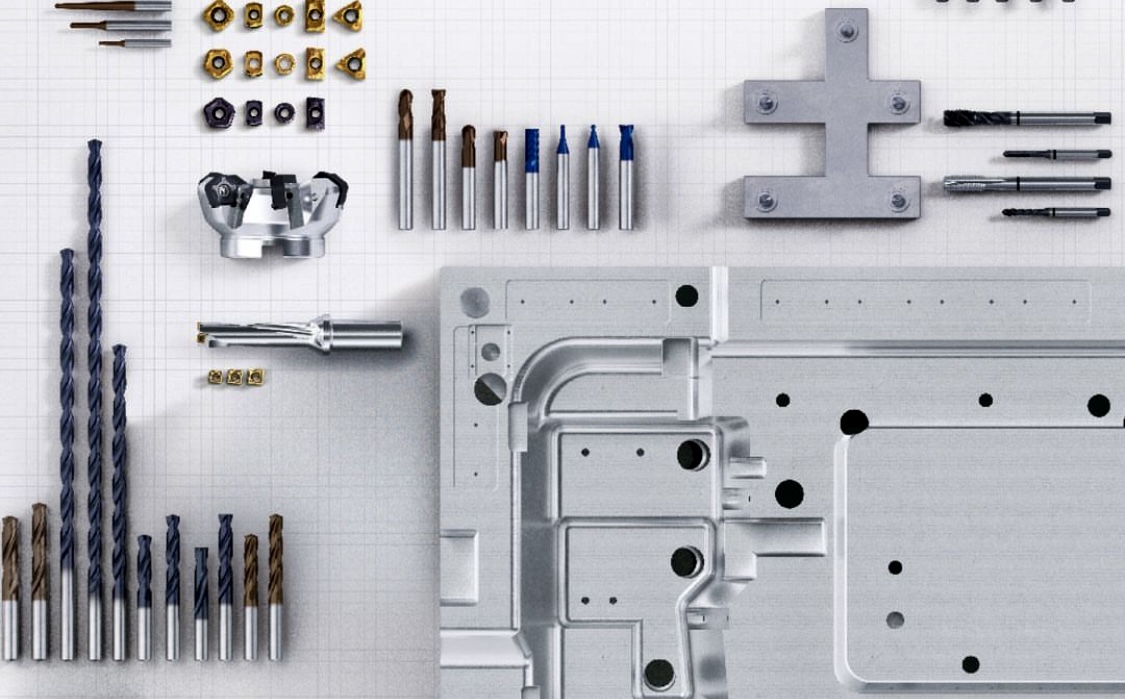

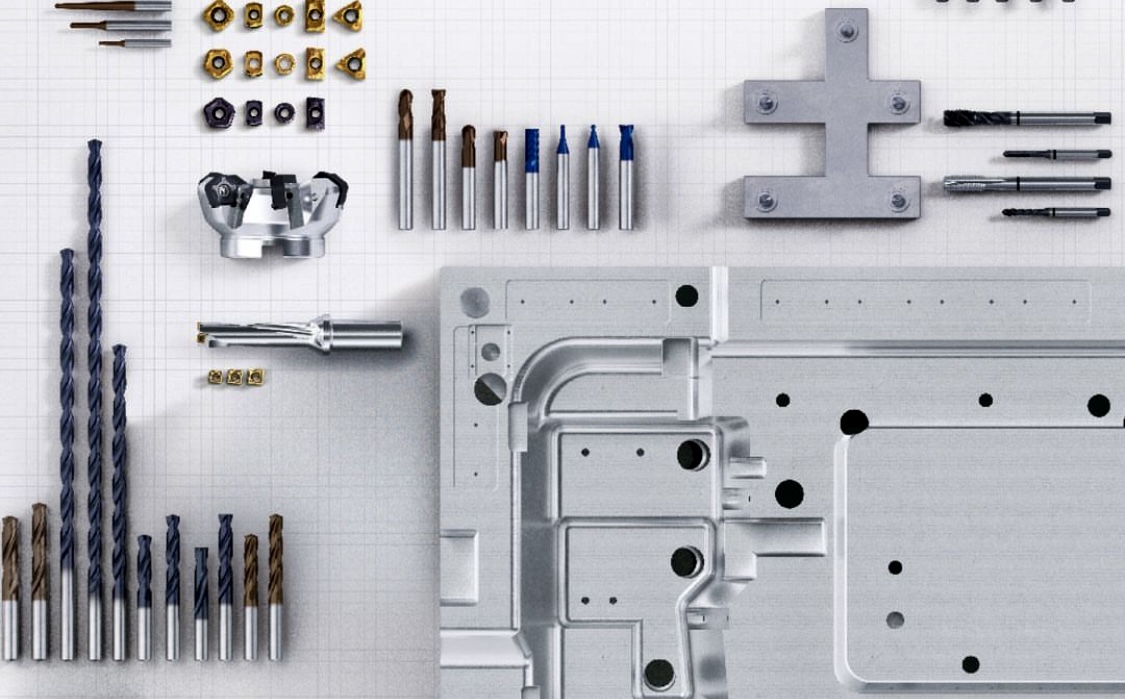

Automobile, machine tool, aviation, mould

10PCS/BOX

| Availability: | |

|---|---|

| Quantity: | |

The PC8315T WNMG080408-DF is a high-performance carbide turning insert specifically engineered for cast iron machining. Developed through extensive material science research, it delivers balanced performance in both continuous and interrupted cutting operations, which are common in cast iron processing. Its unique geometry and advanced coating system are meticulously optimized to withstand the high hardness and inherent abrasiveness of cast iron, thereby ensuring consistent tool life and superior surface finish throughout prolonged production runs. This insert is a reliable choice for manufacturers seeking to enhance machining efficiency while maintaining strict quality standards.

WNMG080408-DF Geometry: The 80° diamond shape, combined with a 0.8 mm corner radius, offers exceptional stability during machining processes. This design significantly reduces edge chipping, even when subjected to heavy cuts, which is crucial for maintaining productivity in high-volume manufacturing .

PC8315T Substrate: Crafted from a fine-grained carbide substrate, this insert boasts enhanced toughness. This characteristic enables it to resist thermal cracking and wear effectively, even when operating at elevated temperatures that are typical in cast iron machining. The substrate's composition is tailored to handle the rigorous demands of continuous contact with hard materials.

Multi-Layer Coating: Utilizing state-of-the-art CVD (Chemical Vapor Deposition) technology, the insert features a combination of TiCN and Al₂O₃ coatings. This multi-layer structure improves hardness, enhances heat resistance, and provides excellent anti-adhesion properties. As a result, tool life is extended by up to 30% compared to uncoated inserts, reducing tool change frequency and associated downtime .

Cutting Speed: 250–300 m/min, suitable for both dry and wet machining environments. The ability to operate in either condition adds flexibility to manufacturing processes.

Feed Rate: 0.08–0.18 mm/rev, accommodating semi-finish to finish machining requirements. This range allows for precise control over surface quality.

Depth of Cut: 0.5–2.0 mm, enabling versatile machining operations across different cast iron components.

Industry: Widely utilized in the automotive, aerospace, and general manufacturing sectors. Its performance characteristics make it a go-to tool in these industries where precision and efficiency are paramount.

Operations: Specialized in semi-finishing and finishing of various cast iron types, including gray cast iron (GG25–GG30), ductile iron (GGG40–GGG60), and compacted graphite iron (CGI). Each of these materials has distinct properties, and the insert adapts well to their machining needs.

Machining Scenarios: Particularly suitable for turning crankshafts, cylinder heads, and gearbox components. In these applications, dimensional accuracy and surface quality are critical to ensure proper functionality and performance of the final products. The insert's consistent performance helps meet these stringent requirements.

Q: How does the PC8315T handle interrupted cuts?

A: The robust substrate and carefully designed coating work in tandem to minimize edge chipping. This makes it highly suitable for intermittent machining operations, such as those encountered when processing flanged components, where the tool repeatedly engages and disengages from the workpiece .

Q: What coolant is recommended?

A: Water-soluble emulsions or synthetic coolants are preferred. These coolants help reduce thermal stress on the insert, which is vital for maintaining its integrity, and also improve chip evacuation, preventing chip buildup that can affect machining quality.

The PC8315T WNMG080408-DF is a high-performance carbide turning insert specifically engineered for cast iron machining. Developed through extensive material science research, it delivers balanced performance in both continuous and interrupted cutting operations, which are common in cast iron processing. Its unique geometry and advanced coating system are meticulously optimized to withstand the high hardness and inherent abrasiveness of cast iron, thereby ensuring consistent tool life and superior surface finish throughout prolonged production runs. This insert is a reliable choice for manufacturers seeking to enhance machining efficiency while maintaining strict quality standards.

WNMG080408-DF Geometry: The 80° diamond shape, combined with a 0.8 mm corner radius, offers exceptional stability during machining processes. This design significantly reduces edge chipping, even when subjected to heavy cuts, which is crucial for maintaining productivity in high-volume manufacturing .

PC8315T Substrate: Crafted from a fine-grained carbide substrate, this insert boasts enhanced toughness. This characteristic enables it to resist thermal cracking and wear effectively, even when operating at elevated temperatures that are typical in cast iron machining. The substrate's composition is tailored to handle the rigorous demands of continuous contact with hard materials.

Multi-Layer Coating: Utilizing state-of-the-art CVD (Chemical Vapor Deposition) technology, the insert features a combination of TiCN and Al₂O₃ coatings. This multi-layer structure improves hardness, enhances heat resistance, and provides excellent anti-adhesion properties. As a result, tool life is extended by up to 30% compared to uncoated inserts, reducing tool change frequency and associated downtime .

Cutting Speed: 250–300 m/min, suitable for both dry and wet machining environments. The ability to operate in either condition adds flexibility to manufacturing processes.

Feed Rate: 0.08–0.18 mm/rev, accommodating semi-finish to finish machining requirements. This range allows for precise control over surface quality.

Depth of Cut: 0.5–2.0 mm, enabling versatile machining operations across different cast iron components.

Industry: Widely utilized in the automotive, aerospace, and general manufacturing sectors. Its performance characteristics make it a go-to tool in these industries where precision and efficiency are paramount.

Operations: Specialized in semi-finishing and finishing of various cast iron types, including gray cast iron (GG25–GG30), ductile iron (GGG40–GGG60), and compacted graphite iron (CGI). Each of these materials has distinct properties, and the insert adapts well to their machining needs.

Machining Scenarios: Particularly suitable for turning crankshafts, cylinder heads, and gearbox components. In these applications, dimensional accuracy and surface quality are critical to ensure proper functionality and performance of the final products. The insert's consistent performance helps meet these stringent requirements.

Q: How does the PC8315T handle interrupted cuts?

A: The robust substrate and carefully designed coating work in tandem to minimize edge chipping. This makes it highly suitable for intermittent machining operations, such as those encountered when processing flanged components, where the tool repeatedly engages and disengages from the workpiece .

Q: What coolant is recommended?

A: Water-soluble emulsions or synthetic coolants are preferred. These coolants help reduce thermal stress on the insert, which is vital for maintaining its integrity, and also improve chip evacuation, preventing chip buildup that can affect machining quality.

Phone: +86-18868651999

Email: eden0906@nekkk.com

Add: ROOM 1-2, 17TH FLOOR, 9TH BUILDING, NO.35, XINGHAI ROAD(NORTH), GAOXIN DISTRICT, NINGBO CITY, ZHEJIANG PROVINCE, CHINA