Please Choose Your Language

CNMG120404-GM PC8220

SHITAEGER

NEK-CN03

Turning Insert

Automobile, machine tool, aviation, mould

10pcs/box

| Availability: | |

|---|---|

| Quantity: | |

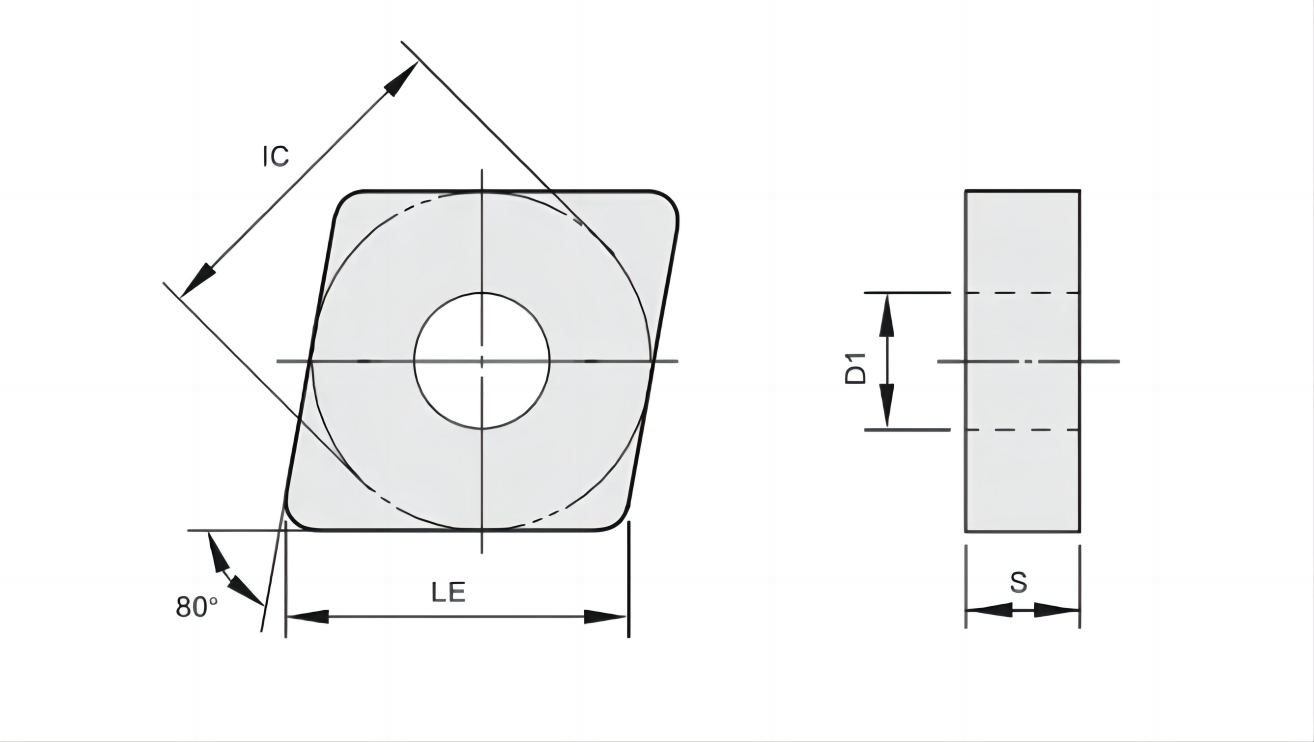

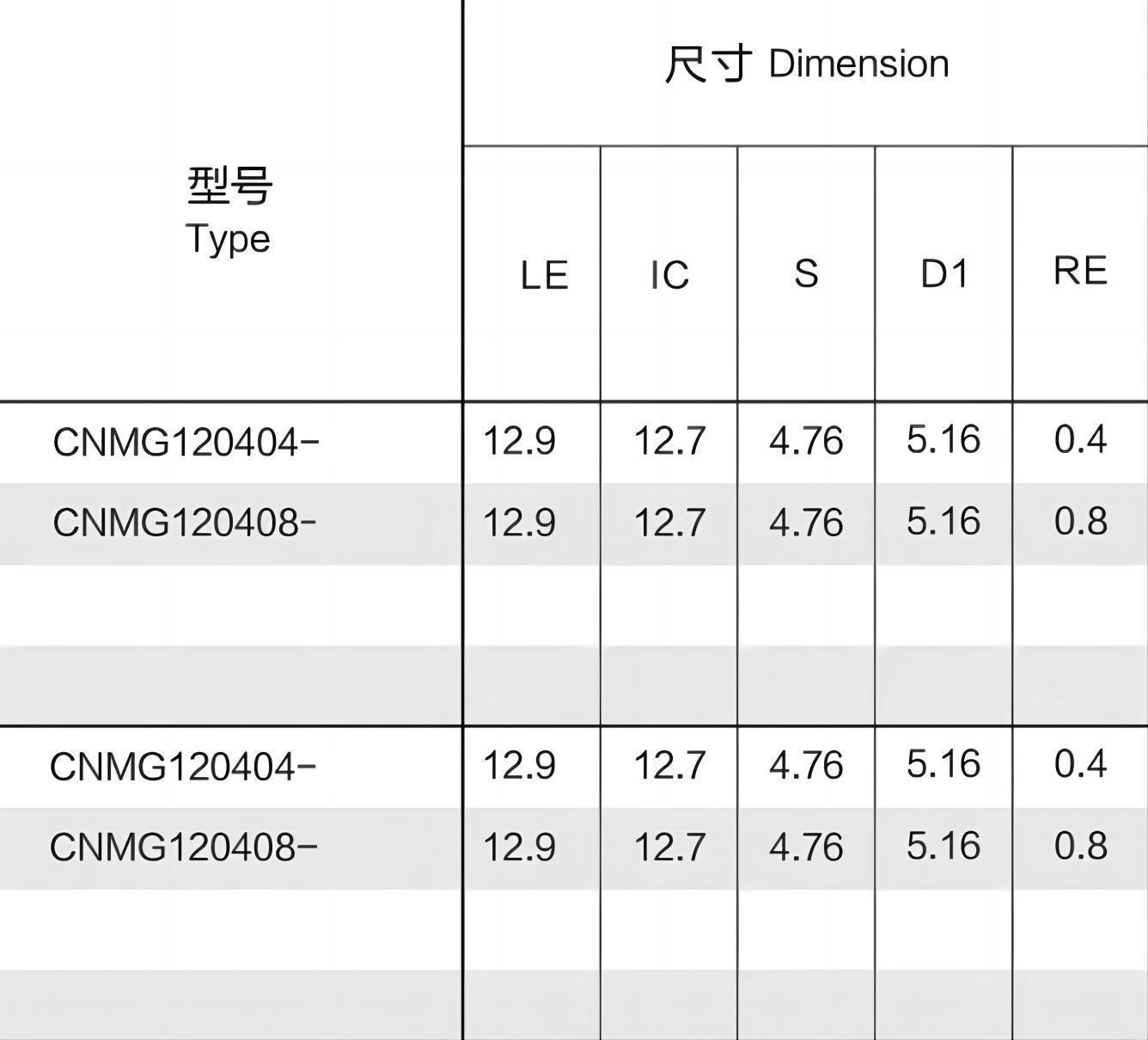

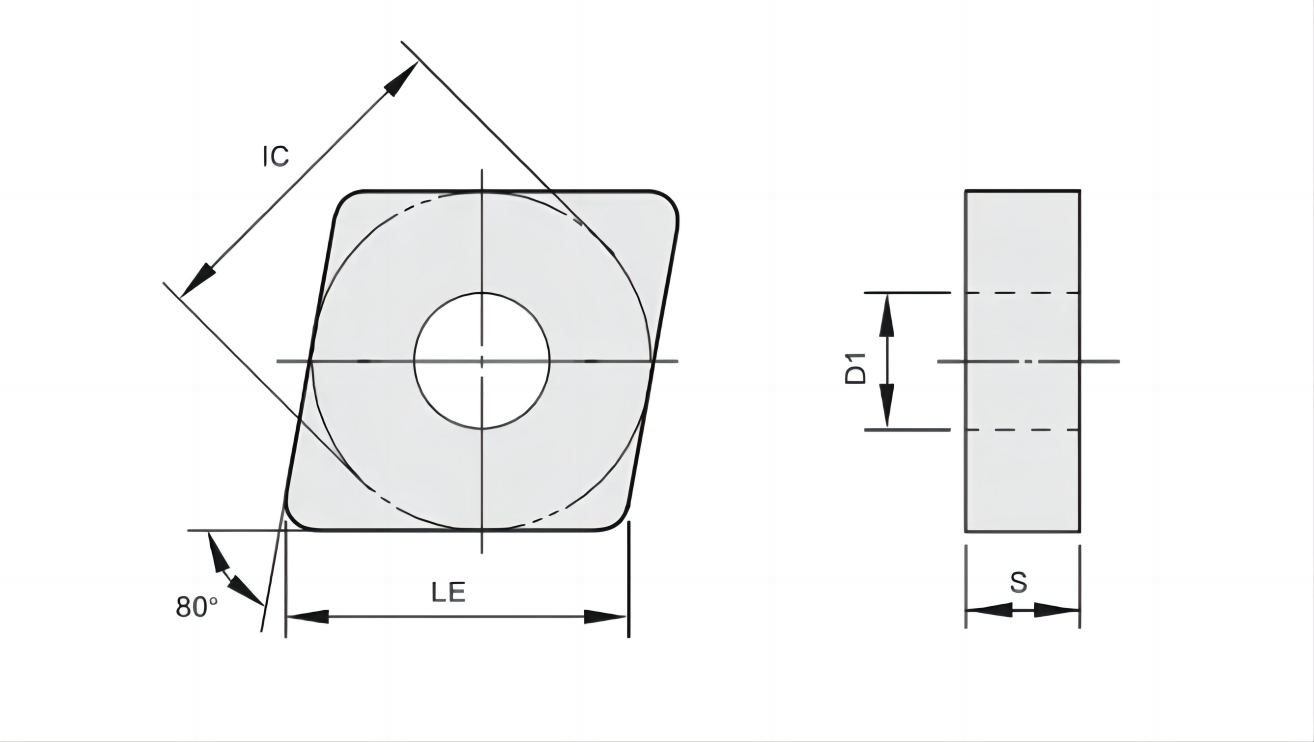

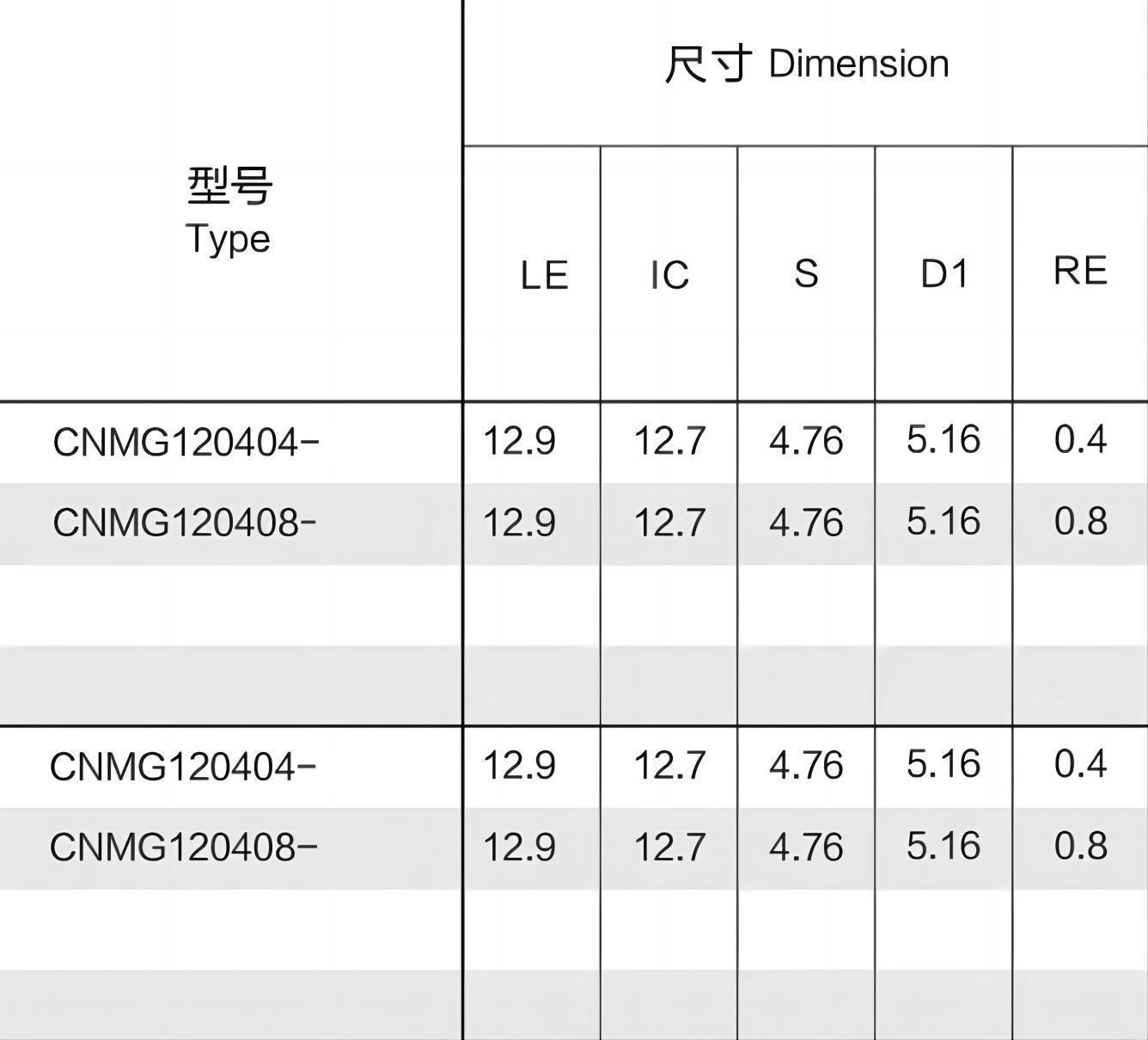

The CNMG120404 turning insert is a premium-grade cutting tool engineered to revolutionize precision machining across diverse industrial applications. Renowned for its exceptional durability and versatility, this indexable insert combines innovative design with cutting-edge materials to deliver unmatched performance in turning, facing, and profiling operations. With an inscribed circle diameter of 12.7mm and a thickness of 4.76mm, the CNMG120404 is optimized for medium to heavy-duty machining, offering stability and strength in high-load conditions. Its negative rake geometry enhances rigidity, minimizing deflection during aggressive cuts, while state-of-the-art coating technology ensures prolonged tool life and consistent results. Compatible with CNC lathes and conventional machinery, this insert is a cornerstone for industries prioritizing efficiency, accuracy, and cost-effectiveness in metalworking processes.

1. Multilayer TiAlN Coating: The insert is fortified with a proprietary PVD (Physical Vapor Deposition) TiAlN coating, which significantly improves surface hardness (up to 3200 HV) and oxidation resistance. This coating withstands temperatures up to 900°C, reducing thermal cracks and extending tool life by up to 50% compared to standard coatings.

2. Advanced Chip Control: The precision-engineered chip breaker features a multi-stage design that generates controlled chip curl and breakage across a wide range of cutting parameters. This minimizes chip entanglement, reduces heat buildup, and enhances surface finish quality, even at high feed rates.

3. Ultra-Fine Carbide Substrate: Constructed from a high-density, ultra-fine grain carbide base, the insert achieves superior wear resistance and edge toughness. This ensures reliable performance in intermittent cutting and hard-to-machine materials like duplex stainless steels and nickel alloys.

4. Multi-Functional Geometry: The 80-degree diamond shape with a 0.4mm nose radius provides versatility for both roughing and finishing. Its dual-sided design offers six usable cutting edges, maximizing cost efficiency and reducing tool change frequency.

5. Enhanced Compatibility: Engineered to ISO 1832 standards, the CNMG120404 seamlessly integrates with industry-standard tool holders, simplifying setup and reducing machine downtime.

The CNMG120404 excels in demanding machining environments across multiple sectors:

· Automotive Manufacturing: Ideal for turning engine blocks, transmission shafts, and brake discs from carbon steel or ductile iron, ensuring tight tolerances and high repeatability.

· Aerospace Engineering: Used in machining turbine discs, landing gear components, and titanium alloy fittings, where heat resistance and precision are paramount.

· Oil and Gas Equipment: Suitable for processing valve bodies, drill collars, and pipeline flanges in corrosion-resistant alloys like Inconel and Hastelloy.

· General Metalworking: Effective in producing hydraulic pistons, bearing housings, and threaded spindles from materials ranging from aluminum to hardened steels (up to 45 HRC).

With its ability to handle high-speed machining (up to 350 m/min) and deep cuts, the CNMG120404 is a trusted solution for achieving superior surface finishes (Ra ≤ 1.6 μm) and maximizing productivity in continuous or interrupted cutting scenarios.

The CNMG120404 turning insert is a premium-grade cutting tool engineered to revolutionize precision machining across diverse industrial applications. Renowned for its exceptional durability and versatility, this indexable insert combines innovative design with cutting-edge materials to deliver unmatched performance in turning, facing, and profiling operations. With an inscribed circle diameter of 12.7mm and a thickness of 4.76mm, the CNMG120404 is optimized for medium to heavy-duty machining, offering stability and strength in high-load conditions. Its negative rake geometry enhances rigidity, minimizing deflection during aggressive cuts, while state-of-the-art coating technology ensures prolonged tool life and consistent results. Compatible with CNC lathes and conventional machinery, this insert is a cornerstone for industries prioritizing efficiency, accuracy, and cost-effectiveness in metalworking processes.

1. Multilayer TiAlN Coating: The insert is fortified with a proprietary PVD (Physical Vapor Deposition) TiAlN coating, which significantly improves surface hardness (up to 3200 HV) and oxidation resistance. This coating withstands temperatures up to 900°C, reducing thermal cracks and extending tool life by up to 50% compared to standard coatings.

2. Advanced Chip Control: The precision-engineered chip breaker features a multi-stage design that generates controlled chip curl and breakage across a wide range of cutting parameters. This minimizes chip entanglement, reduces heat buildup, and enhances surface finish quality, even at high feed rates.

3. Ultra-Fine Carbide Substrate: Constructed from a high-density, ultra-fine grain carbide base, the insert achieves superior wear resistance and edge toughness. This ensures reliable performance in intermittent cutting and hard-to-machine materials like duplex stainless steels and nickel alloys.

4. Multi-Functional Geometry: The 80-degree diamond shape with a 0.4mm nose radius provides versatility for both roughing and finishing. Its dual-sided design offers six usable cutting edges, maximizing cost efficiency and reducing tool change frequency.

5. Enhanced Compatibility: Engineered to ISO 1832 standards, the CNMG120404 seamlessly integrates with industry-standard tool holders, simplifying setup and reducing machine downtime.

The CNMG120404 excels in demanding machining environments across multiple sectors:

· Automotive Manufacturing: Ideal for turning engine blocks, transmission shafts, and brake discs from carbon steel or ductile iron, ensuring tight tolerances and high repeatability.

· Aerospace Engineering: Used in machining turbine discs, landing gear components, and titanium alloy fittings, where heat resistance and precision are paramount.

· Oil and Gas Equipment: Suitable for processing valve bodies, drill collars, and pipeline flanges in corrosion-resistant alloys like Inconel and Hastelloy.

· General Metalworking: Effective in producing hydraulic pistons, bearing housings, and threaded spindles from materials ranging from aluminum to hardened steels (up to 45 HRC).

With its ability to handle high-speed machining (up to 350 m/min) and deep cuts, the CNMG120404 is a trusted solution for achieving superior surface finishes (Ra ≤ 1.6 μm) and maximizing productivity in continuous or interrupted cutting scenarios.

Phone: +86-18868651999

Email: eden0906@nekkk.com

Add: ROOM 1-2, 17TH FLOOR, 9TH BUILDING, NO.35, XINGHAI ROAD(NORTH), GAOXIN DISTRICT, NINGBO CITY, ZHEJIANG PROVINCE, CHINA