Please Choose Your Language

NEK

1

1

40cr 20crmnti

Car

1 Box- 1 P

CNC Tool

| Availability: | |

|---|---|

| Quantity: | |

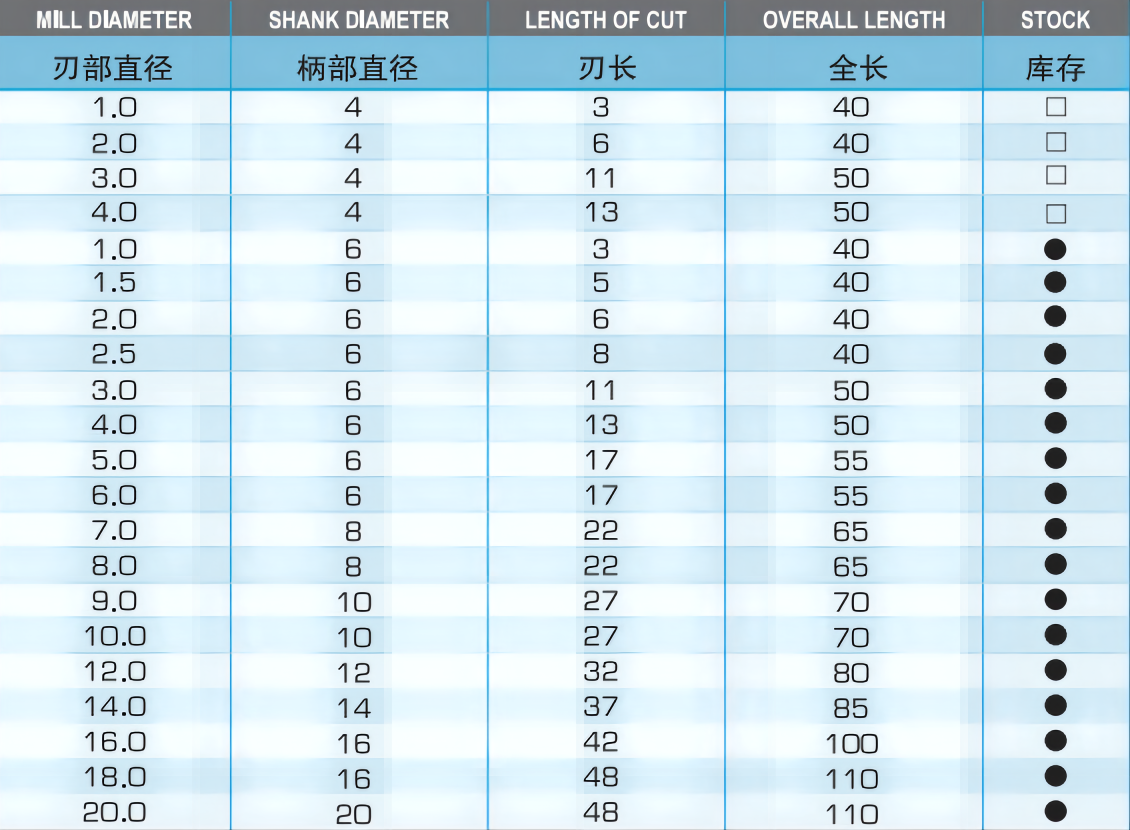

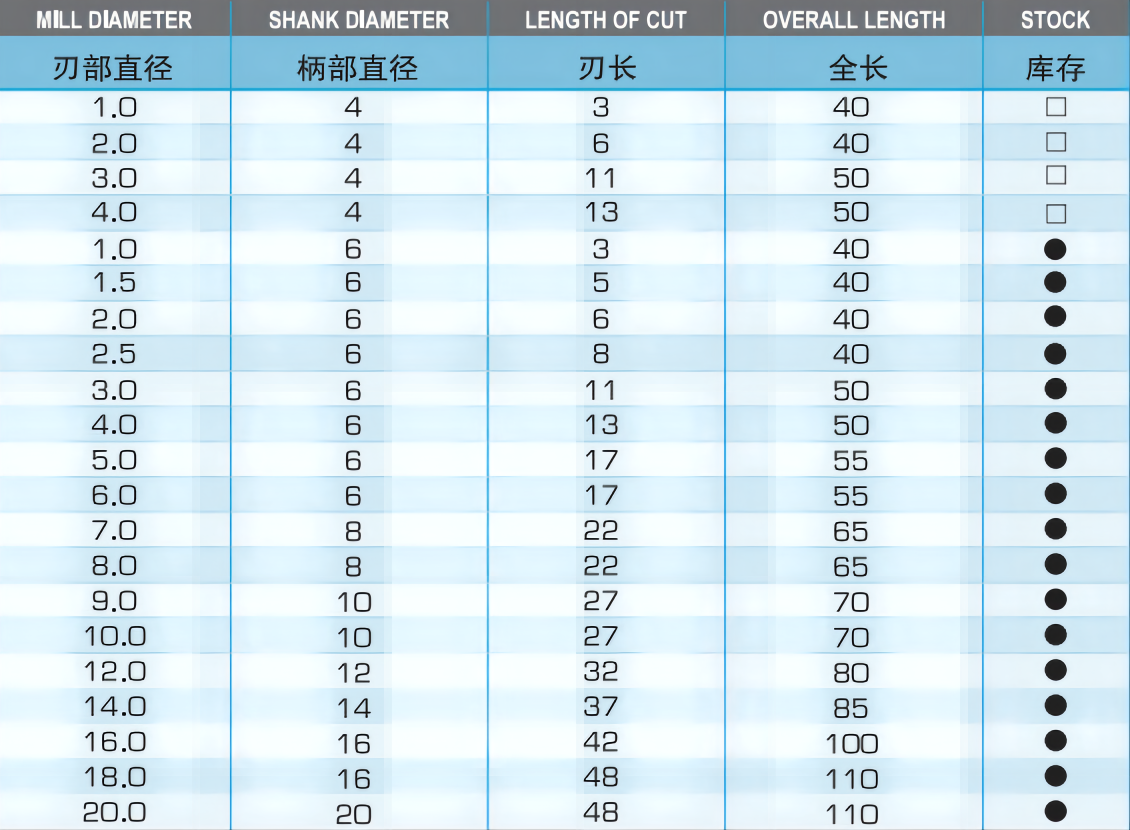

CNC blade is a tool for cutting, usually composed of blade and handle. CNC blade design precision, can achieve high-speed, efficient cutting processing. Different types of CNC blades are suitable for different cutting requirements, such as plane blade, chamfer blade, cutting slot blade, etc.

CNC milling tool materials are mainly the following:

1. Cemented carbide: By tungsten, cobalt, titanium and other metal powder and carbide mixed, after high temperature sintering, with high hardness and wear resistance.

2. High-speed steel: containing more tungsten, chromium, molybdenum and other alloying elements, with high hardness and heat resistance, can maintain good cutting performance at higher cutting temperatures.

3. Ceramics: with high hardness, high wear resistance and high thermal hardness, but the bending strength and toughness are low, suitable for high-speed cutting.

4. Cubic boron nitride (CBN) and polycrystalline diamond (PCD) : These two materials have extremely high hardness and wear resistance, suitable for processing high-hardness materials and ultra-precision cutting.

1. High precision: CNC milling cutter adopts advanced manufacturing technology and accurate measurement means to ensure the high precision and high quality of the tool.

2. High efficiency: Because CNC milling cutter adopts computer program control processing, high-speed cutting and automated production can be achieved, improving production efficiency.

3. Good stability: CNC milling cutter in the cutting process, due to the optimization of tool materials and structure, can maintain a better cutting state, improve processing stability.

4. Strong adaptability: CNC milling cutter can choose the appropriate tool materials and geometric parameters according to different processing needs, which is suitable for the processing of various shapes and sizes of the workpiece.

1. High machining accuracy: CNC milling cutter can achieve micron-level machining accuracy to meet the processing needs of high-precision parts.

2. High processing efficiency: CNC milling cutter adopts high-speed cutting technology, which can significantly improve processing efficiency and shorten the production cycle.

3. Extended Tool Longevity: The CNC milling cutter boasts a prolonged tool life thanks to its premium materials and cutting-edge manufacturing techniques, ultimately leading to decreased production costs.

4. Achieve complex shape processing: CNC milling cutter can process a variety of complex shape of the workpiece, such as curves, surfaces, spiral, etc., expand the processing range.

1. Aerospace field: CNC milling cutter is suitable for processing a variety of high-precision parts in the aerospace field, such as engine blades, turbine disks, etc.

2. Automotive manufacturing field: CNC milling cutter can be used to process automotive engine parts, body structural parts, etc., to improve production efficiency and processing accuracy.

3. Mold manufacturing field: CNC milling cutter can process various mold parts, such as mold cavity, core, etc., to meet the high precision and high quality requirements of mold manufacturing.

4. CNC Milling Cutter in Electronic Communication Industry: The CNC milling cutter is ideal for manufacturing a wide range of electronic components and communication equipment parts, including mobile phone casings and circuit boards.

In short, CNC milling tools have the characteristics and advantages of high precision, high efficiency, good stability and strong adaptability, and are widely used in aerospace, automobile manufacturing, mold manufacturing and electronic communications and other fields. When selecting a CNC milling cutter, the appropriate tool material and geometric parameters should be selected according to the specific processing requirements and workpiece materials.

CNC blade is a tool for cutting, usually composed of blade and handle. CNC blade design precision, can achieve high-speed, efficient cutting processing. Different types of CNC blades are suitable for different cutting requirements, such as plane blade, chamfer blade, cutting slot blade, etc.

CNC milling tool materials are mainly the following:

1. Cemented carbide: By tungsten, cobalt, titanium and other metal powder and carbide mixed, after high temperature sintering, with high hardness and wear resistance.

2. High-speed steel: containing more tungsten, chromium, molybdenum and other alloying elements, with high hardness and heat resistance, can maintain good cutting performance at higher cutting temperatures.

3. Ceramics: with high hardness, high wear resistance and high thermal hardness, but the bending strength and toughness are low, suitable for high-speed cutting.

4. Cubic boron nitride (CBN) and polycrystalline diamond (PCD) : These two materials have extremely high hardness and wear resistance, suitable for processing high-hardness materials and ultra-precision cutting.

1. High precision: CNC milling cutter adopts advanced manufacturing technology and accurate measurement means to ensure the high precision and high quality of the tool.

2. High efficiency: Because CNC milling cutter adopts computer program control processing, high-speed cutting and automated production can be achieved, improving production efficiency.

3. Good stability: CNC milling cutter in the cutting process, due to the optimization of tool materials and structure, can maintain a better cutting state, improve processing stability.

4. Strong adaptability: CNC milling cutter can choose the appropriate tool materials and geometric parameters according to different processing needs, which is suitable for the processing of various shapes and sizes of the workpiece.

1. High machining accuracy: CNC milling cutter can achieve micron-level machining accuracy to meet the processing needs of high-precision parts.

2. High processing efficiency: CNC milling cutter adopts high-speed cutting technology, which can significantly improve processing efficiency and shorten the production cycle.

3. Extended Tool Longevity: The CNC milling cutter boasts a prolonged tool life thanks to its premium materials and cutting-edge manufacturing techniques, ultimately leading to decreased production costs.

4. Achieve complex shape processing: CNC milling cutter can process a variety of complex shape of the workpiece, such as curves, surfaces, spiral, etc., expand the processing range.

1. Aerospace field: CNC milling cutter is suitable for processing a variety of high-precision parts in the aerospace field, such as engine blades, turbine disks, etc.

2. Automotive manufacturing field: CNC milling cutter can be used to process automotive engine parts, body structural parts, etc., to improve production efficiency and processing accuracy.

3. Mold manufacturing field: CNC milling cutter can process various mold parts, such as mold cavity, core, etc., to meet the high precision and high quality requirements of mold manufacturing.

4. CNC Milling Cutter in Electronic Communication Industry: The CNC milling cutter is ideal for manufacturing a wide range of electronic components and communication equipment parts, including mobile phone casings and circuit boards.

In short, CNC milling tools have the characteristics and advantages of high precision, high efficiency, good stability and strong adaptability, and are widely used in aerospace, automobile manufacturing, mold manufacturing and electronic communications and other fields. When selecting a CNC milling cutter, the appropriate tool material and geometric parameters should be selected according to the specific processing requirements and workpiece materials.

Phone: +86-18868651999

Email: eden0906@nekkk.com

Add: ROOM 1-2, 17TH FLOOR, 9TH BUILDING, NO.35, XINGHAI ROAD(NORTH), GAOXIN DISTRICT, NINGBO CITY, ZHEJIANG PROVINCE, CHINA